Selecting a suitable tube laser cutting machine becomes essential for companies, mainly for those who need precision and efficient, and high-volume production. The machines serve essential functions in automotive and aerospace, together with the construction sectors, because accuracy and productivity remain vital elements. The selection process for the best machine becomes complex because of the numerous available options. As explained in this article, selecting an appropriate laser cutting machine for tubes requires evaluating essential factors that match your business requirements.

Understanding the Different Types of Tube Laser Cutting Machines

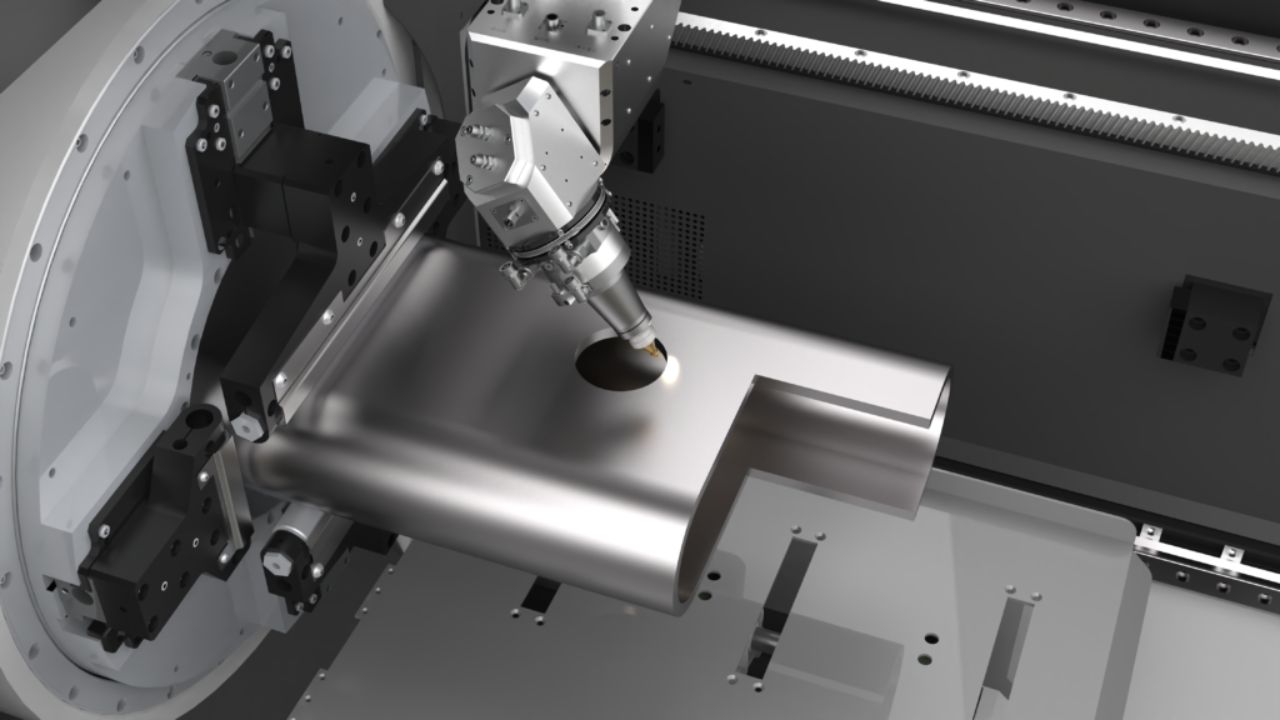

The process of selecting begins with comprehending the available machine types. Different machine configurations exist to fulfill distinct cutting requirements. The available tube laser cutting machines operate either on round tubes or square or rectangular tubes. Specialized machines exist to cut both simple and complex shapes and profiles. The choice of a tube laser cutting machine depends entirely on what type of tube requires cutting.

To make a selection between specialized or multi-purpose tube machines, a business must analyze its production requirements. Tubes requiring intricate shapes benefit most from machines equipped with multi-axis control systems. High-power laser machines deliver both the speed and power required by businesses that need to optimize their heavy-duty production operations.

Laser Power and Efficiency

The selection requires a determination of the necessary laser power levels. The measurement unit for laser power is watts. A machine with higher wattage levels enables faster and more efficient cutting of thick materials. The required power of the tube laser cutting machine depends on the tube wall thickness because thin-walled tubes need less power, but construction and heavy-duty industries require higher power machines.

The machine’s operational efficiency stands as a vital factor to consider. The laser power output should be evaluated by businesses to determine its impact on processing speed and operational throughput. The increased power capacity of machines enables them to cut materials at higher speeds, thus shortening production durations. Businesses need to find the right equilibrium between fast operation and exact results. Manufacturers need machines with sub-millimeter precision to deliver high-quality outcomes in their operations.

Precision and Accuracy

The selection of a tube laser cutting machine requires precision to be among the most important features. The aerospace and automotive manufacturing sectors require their equipment to achieve exceptional accuracy levels for maintaining strict quality requirements. A machine that delivers precise cuts decreases material waste while eliminating post-processing requirements and guarantees products meet their specified requirements.

The machine operator needs to know its operational tolerance range. The production of complex parts requires precise tolerances because minor dimensional errors will produce unusable end products. The combination of AI-driven multi-axis control systems with machines enables exceptional accuracy, which maintains precision levels during high-volume production runs.

Automation and Customization

Modern tube laser cutting machines feature automation as their essential operational characteristic. Companies need to select machines that incorporate automatic features for material feeding and nesting, and unloading operations. The automated features decrease the necessity of human operators, which leads to better efficiency and safety conditions on the production floor.

Businesses should evaluate customization options when making their selection. The production requirements of certain businesses demand particular modifications to their equipment. Businesses that find machines with customizable software and adaptable cutting heads for specialized tasks will achieve better long-term efficiency and return on investment.

Cost Considerations

The total cost of owning a tube laser cutting machine extends beyond its initial acquisition price because businesses must account for operational expenses throughout its operational life. Businesses must evaluate the total investment return through ROI when comparing machines that cost more because they provide advanced capabilities and better efficiency. The calculation of anticipated production time savings and material waste reduction, and energy efficiency should help businesses decide if they should invest in the higher initial cost.

Companies need to include both the regular maintenance expenses and operational expenses in their calculations. Machines that need minimal maintenance and possess energy-saving capabilities will decrease operational expenses throughout their operational lifespan.

Conclusion

In conclusion, businesses need to evaluate multiple essential factors when choosing a tube laser cutting machine because they must determine the tube material type and laser power strength and precision level and automation capabilities, and ongoing maintenance support. Businesses can select the optimal tube laser cutting machine through a specific business need assessment and machine feature comparison to enhance production efficiency and minimize costs while improving product quality. The selection of appropriate equipment enables businesses to maintain their competitive edge and fulfill the requirements of contemporary manufacturing systems.