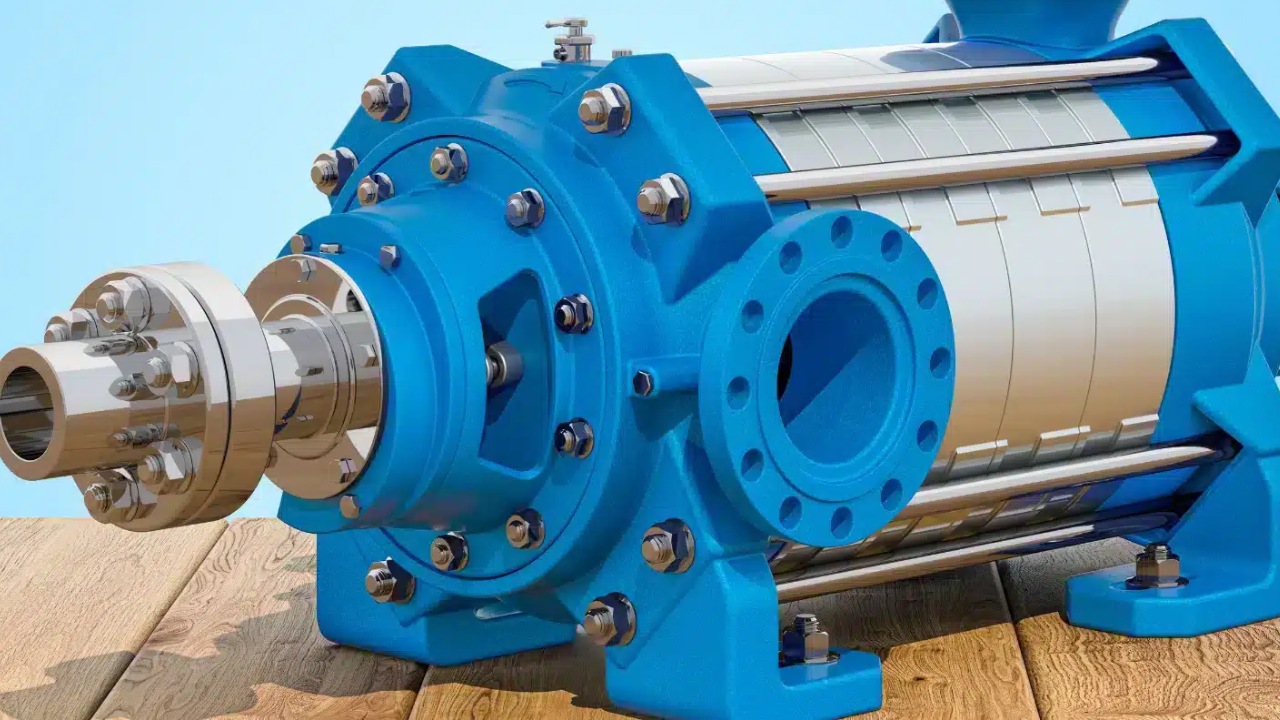

In industrial manufacturing, the attainment of international certifications stands as a recognition of a company’s commitment and dedication to quality, precision, and reliability. For GTC Industrial Pumps, the acquisition of ISO 9001 and API 610 certifications is a reflection of the uncompromising quality that it strives to achieve. These certifications are the first of many that are needed to build the foundation for GTC’s reputation in supplying high-performance pumps to the industries that require excellent quality petrochemical pumps. GTC’s api pump delivers reliable performance and safety for demanding petrochemical and industrial applications.

Setting the Benchmark

GTC is highly inclined to the satisfaction of its customers, which is the primary motivation in the attainment of ISO 9001 and API 610 certifications, more specifically, the provision of products customers can depend on for safe, reliable, and efficient fluid transfer. ISO 9001, which is the dominant quality management system standard in the world, provides a sustainable quality infrastructure across all processes in an organization. Conversely, API 610 provides the standard in which centrifugal pumps for the petroleum, petrochemical, and gas industries are designed and manufactured to extreme specifications.

GTC has streamlined internal management systems, improving the reliability and traceability of every pump that’s produced. Each pump also demonstrates the benefits of GTC’s philosophy that “quality” is not an objective, but rather an integrated continuous improvement endeavor throughout all production phases.

Fostering Quality and Precision Awareness

Establishing an international quality management system begins with corporate ethos, which, at GTC, was the culture of building quality systems and accountability at all levels, which included training all employees, even the production workforce. This ensured every person in the organization was imbued with the ethos of quality.

Every manufacturing process discipline, including design, material choice, machining, and assembly, is executed in conformity with ISO 9001 standards. GTC’s system on documentation, traceability, and process regulation is to eliminate variability. This proactive approach enables GTC to mitigate adverse issues that could impact the production of pumps, all of which are built to meet stringent performance standards.

Excellence in Engineering to API 610 Standards

API 610 certified pumps showcase the engineering excellence of GTC. For the Gulf countries, the API 610 standard deals with the design, construction, and centrifugal pumps built in the toughest industrial climate. This is done especially in the petrochemical and refinery operations. For GTC to qualify, their engineers have to do detailed stress and compatibility analyses, performance simulations, and other evaluations to ensure mechanical and operational safety.

For the production units to perform the tasks explained in the previous paragraph, they have to be equipped with advanced machining and testing apparatus. This enables the management and validation of the critical parameters of construction, like flow, efficiency, vibration, temperature, and resistance, in the petrochemical and refinery operations. All pumps are tested and validated in performance before they are released to the clients, and the tests are in compliance with the API specifications, which verify operational reliability.

GTC is the only company in the Gulf compliant to API 610, which focuses on thrust performance testing of pumps to guarantee reliability under extreme operational conditions of pressure, temperature, and aggressive chemicals in API compliant pumps to approved GTC standards.

Continuous Improvement and Quality Management

GTC does not stop at certifications; they are essential, but GTC views each one as part of a longer journey toward excellence. ISO 9001 certified GTC’s Quality Management System (QMS) means every one of their processes is monitored, assessed, and improved every step of the way. GTC’s quality is maintained and enhanced to meet customer expectations, legal obligations, and adjusted by internal audits and registered customer feedback, which continues to control quality and improve responsiveness.

GTC’s devotion to quality and continuous improvement prioritizes its R&D initiatives, too. GTC continues to improve the efficiency, corrosion resistance, and energy savings of its pumps and many other GTC-manufactured products by the use of new materials, innovative designs, and production technologies. In the R&D quality and innovative improvements vision, GTC ensures that GTC products go beyond international expectations and standards.

Conclusion

The story behind GTC earning ISO 9001 and API 610 certifications highlights the company’s commitment. This ensures quality, innovation, and the constant pursuit of excellence. GTC now operates with advanced engineering control, integrated process control, and a culture of continuous improvement to achieve its goal as a leader in industrial pumping solutions. To the company, these certifications are a testament to GTC’s commitment to launching world-class products while meeting the various international expectations in reliability, safety, and performance, and to further excellence in its industrial pumping solutions.